Release time:2024-05-07

"Yu," you make an appointment. There is "lithium" in the mountain city

2024 Chongqing CIBF

01

In the global wave of new energy development, battery technology, with its unique charm and potential, is leading the direction of industry development. Chongqing, as the first stop of the CIBF tour, has become a highland in the Southwest battery industry with its geographical and resource advantages. It also serves as a node for the China Europe shuttle bus and the land sea new channel, promoting the global export of battery products.

On April 29th, the 16th Chongqing International Battery Technology Exchange Conference/Exhibition of CIBF2024 came to a successful conclusion, and ShenFaYuan Ultrasonic also ended its three-day CIBF journey. At this globally acclaimed event, DeepSource brought numerous excellent welding solutions for lithium-ion batteries and an online visual tracking glue dispenser to the exhibition, providing more possibilities for the development of the new energy industry.

Direct on-site attack

2024 Chongqing CIBF

02

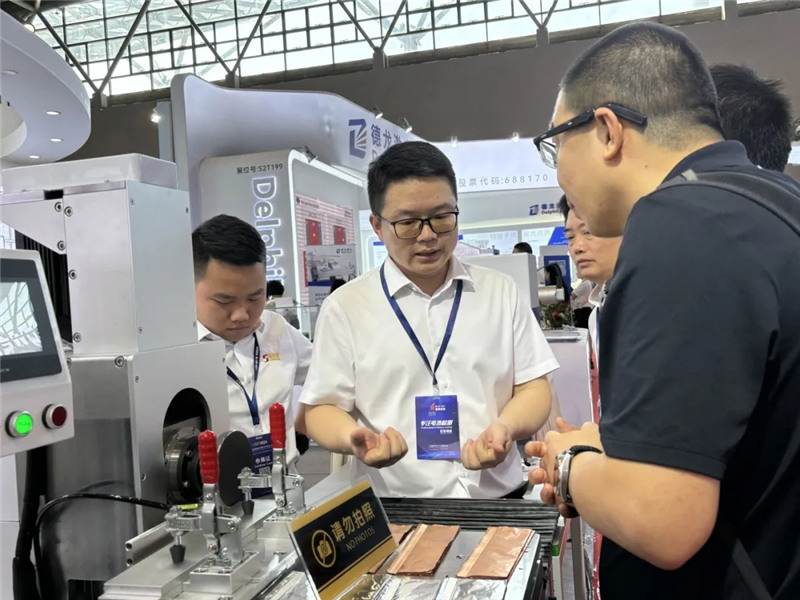

As a well-known expert in lithium battery welding solutions in China, Deep Source Ultrasonic attracted many domestic and foreign appearance exhibitors to stop and consult during the exhibition period with advanced welding technology and leading welding equipment.

The recognition of our customers and the market is the unremitting driving force behind our efforts, persistence, and progress at the source of deep development. At this CIBF exhibition, Deep Source Ultrasonic delivered a satisfactory answer to the market, and at the same time, we also witnessed the strength of China's manufacturing industry. There is still a long way to go for Deep Source in the future, and we sincerely invite you to witness!

Entering Deep Source Ultrasound

2024 Chongqing CIBF

03

Shenzhen Shenfangyuan Precision Technology Co., Ltd. (referred to as Shenfangyuan Ultrasonic) has been focusing on the field of ultrasonic welding of power battery pole ears since its establishment in 2010. After more than a decade of cultivation, it has grown into a leading supplier of ultrasonic equipment in China, and related equipment has been widely used in leading lithium battery enterprises in China.

The welding equipment showcased at this CIBF exhibition is only a small part of ShenFaYuan. Since its development, ShenFaYuan's ultrasonic equipment category has been very diverse, mainly covering four major sectors: ultrasonic lithium battery welding solutions, ultrasonic automotive wire harness welding solutions, ultrasonic IGBT semiconductor packaging solutions, and ultrasonic plastic welding solutions. In addition, the production and maintenance capabilities of the accessories of Deep Source Ultrasonic are top-notch.

Deep Source Ultrasonic Excellent Welding Solution (Part)

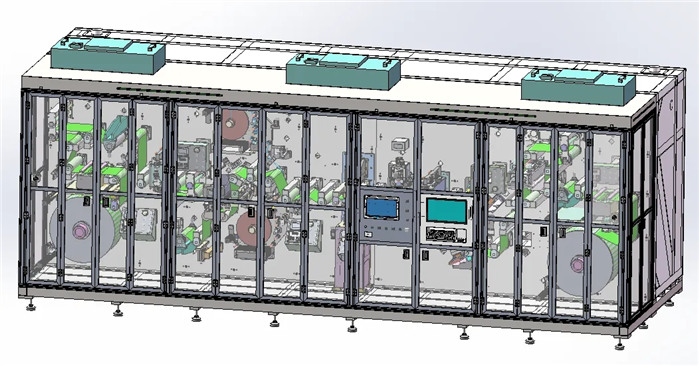

Pole cutting, rolling, welding, and gluing integrated machine

Mainly suitable for laminating composite current collectors and upper and lower foils, as well as ultrasonic welding.

Welding layers: 2 layers of composite material, 1 layer of composite foil material

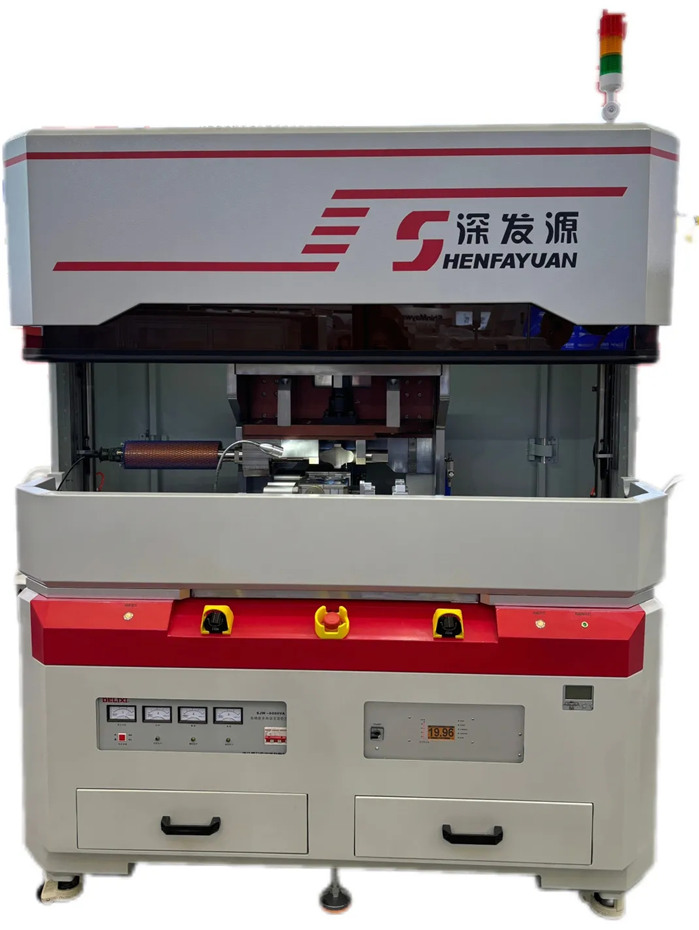

20K ultrasonic multi-layer rolling welding machine

The 20K ultrasonic multi-layer rolling welding machine is a new application for traditional spot welding. It can complete ultra long welding in one go and is suitable for welding long distances, multi-layer foil welding, and other weldable materials.

Power: 3000W-8000W Welding layers: 10-100 layers

Advantages: 1. Welding length reaches 300mm. 2. Welding points are uniform, stable, and flat. 3. Welding positioning is accurate. 4. Welding quality is stable, reliable, and efficient.

Ultrasonic full wave wire harness terminal welding machine

The ultrasonic full wave wire harness terminal welding machine is used for welding various copper terminals and wire harnesses. The wiring harness does not require shaping, and can be directly connected to one or more wiring harnesses and terminals to control the width of welding.

Power: 6000W-12000W

Welding area: 50mm ²- 120mm ²

Advantages: 1. Safety alarm device 2. Simple operation and easy maintenance 3. Low energy consumption and processing cost 4. Stable and reliable welding quality, high efficiency

5. Monitor every welding process throughout to ensure quality6. Welding height protection setting to prevent empty welding.

20KHZ ultrasonic plastic welding machine

Deep Source 20K Ultrasonic Plastic Welding Machine is a technology for welding plastic products. Various thermoplastic components can be treated with ultrasonic welding without the need for solvents, adhesives, or other auxiliary materials.

Its advantages include increasing productivity multiple times, reducing costs, improving product quality, and ensuring safe production.

For more excitement, please move to the official website of Deep Source Ultrasound!!!

Although the 2024 CIBF exhibition has come to an end, Deep Source Ultrasonic will continue to innovate and seize the opportunities of the times, build core competitive advantages, provide customers with better products and services, cross mountains and seas with a spirit of progress, and go to the future with a spirit of perseverance, contributing more and better welding solutions to the lithium battery industry and empowering China's manufacturing industry!

微信视频号

微信二维码

微信公众号

抖音二维码