Release time:2024-06-25

Warm congratulations, Shenyuan Precision Technology Co., Ltd. (hereinafter referred to as Shenyuan) has independently developed a composite fluid collection roller welding machine, which is about to be launched! Stay tuned from all sectors of society!

Deep Source Composite Current Collector Roller Welding Machine

Composite current collector is a new type of current collector material for power batteries, with a sandwich like sandwich structure. The middle layer is a conductive plastic film made of polymer insulating resin PET/PP and other materials. The two sides of the conductive film are made of metal aluminum/copper with a thickness of about 20-80nm by magnetron sputtering/vacuum evaporation, respectively, to produce a composite current collector.

Lithium batteries have been widely used due to their high energy density, excellent cycling performance, and high discharge rate. However, the current collector positive electrode of conventional lithium-ion batteries usually uses metal aluminum foil, and the negative electrode usually uses metal copper foil. However, once a short circuit occurs inside the battery, the current cannot be cut off, which ultimately leads to heat accumulation and causes thermal runaway. The safety issues caused by thermal runaway are very obvious.

In recent years, researchers have adopted a new type of current collector to replace conventional metal current collectors. This type of composite current collector usually uses non-conductive polymer films as substrates, and a layer of metal is deposited on both sides of the substrate through vacuum evaporation, electroplating, and other methods. For example, metal aluminum is plated on both sides of PET (polyethylene terephthalate) film as the positive electrode current collector, and metal copper is plated on both sides of PP (polypropylene ester) film as the negative electrode current collector. These composite current collectors have improved the safety performance of the battery to a certain extent, while also reducing the weight of the current collector and further increasing the weight energy density of the battery. Based on the above advantages, composite current collectors are widely used in the manufacturing process of lithium batteries.

As a professional expert in lithium battery welding solutions, DeepSource seized the opportunity and actively carried out technological innovation based on years of experience. They have successively developed a series of ultrasonic roller welding machine models and the current slitting roller welding and coating integrated machine, mainly used for welding composite current collectors, to assist lithium battery manufacturers in achieving rapid product launch and profitability.

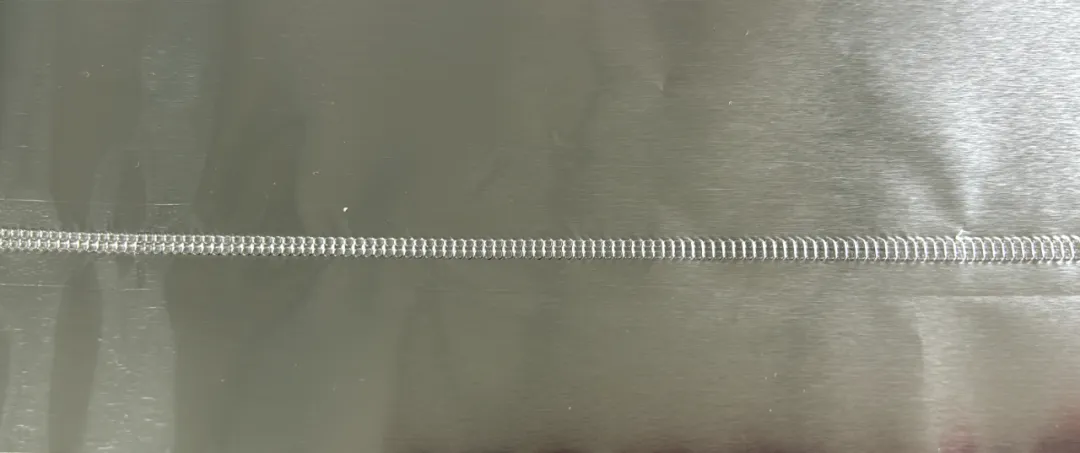

Composite current collector roller welding sample - aluminum

Shenyuan Source was founded in 2010 and is a modern technology innovation manufacturing enterprise that integrates research and development, design, production, sales, and service. It is a high-tech enterprise and a specialized, refined, and innovative small and medium-sized enterprise in Guangdong Province. For many years, the company has been committed to providing lithium battery welding solutions, automotive wire harness welding solutions, semiconductor IGBT packaging welding solutions, home appliance refrigeration industry welding solutions, non-woven plastic welding solutions, and more, with its own technology as the core. It is one of the leading ultrasonic enterprises in China.

Shenyuan not only has an excellent design and development team, but also a strong production team. The enterprise has its own CNC machining workshop, grinding machines, milling machines, lathes, wire cutting, general cutting machines, assembly departments, quality departments, etc., which can respond to customer needs in a timely and efficient manner and provide satisfactory services to customers.

Technological innovation is the driving force for the vigorous development of enterprises. In the future, DeepSource will continue to increase research and development investment, expand its research and development team, and continuously provide customers with higher quality and more efficient welding solutions, empowering China's manufacturing industry.

微信视频号

微信二维码

微信公众号

抖音二维码